Company Profile

Founded in 1999, Dalian SATAKE Chemical Machinery Co., Ltd. is located in the beautiful coastal city of Dalian Lushunkou, Liaoning. It is the joint manufacturer of Dalian Jiuzhou Chemical Machinery Co., Ltd. and the internationally renowned mixer manufacturer - SATAKE Chemical Machinery Industry Co., Ltd. The joint venture company established is the production base of SATAKE Series mixers in China.

Since 1920, SATAKE has focused on the development, design and manufacture of mixers. It has the largest mixing technology research institute in Asia. It has nearly 100 years of experience in the design and manufacture of mixers, and has accumulated a wide range of industry application performance. In dozens of application areas...

The company was founded in 1999

Applied to dozens of application areas

Invested more than 90 million yuan

150 employees

We are committed to building Dalian SATAKE into a century-old enterprise in the mixing industry!

Your satisfaction is our unremitting pursuit!

Dalian SATAKE sincerely appreciates the support and care of our customers!

Yours support & help would be appreciated and thanks very much!

Product Center

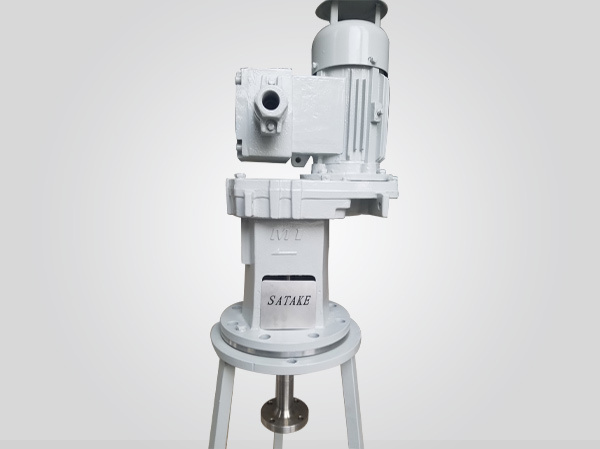

Dalian SATAKE has a wide range of mixers for large, medium and small series, from flexible and compact mobile mixers, maintenance-free M series, gear type M series medium speed mixers, large and medium-sized D series, E series, H ( K) series mixer products, as well as S series belt speed reducer products specially suitable for food, medicine and water treatment industries, G series, L series mixers, C series magnetic stirring and Q series pneumatic stirring specially designed for special needs.

News Centre

For more than ten years, we have established long-term and stable partnerships with many customers at home and abroad. Our products are exported to Africa, Southeast Asia, Middle East, South America, Latin America and other regions. As a manufacturer with rich research and development experience, SATAKE can not only provide users with various forms of mixer products, but also meet the different needs of users. It can also provide users with a complete set of mixing solutions to manufacture products specially designed for you.

03-18

Method for extending the service life of mixer equipment manufacturers

The material selection of the mixer manufacturer is to choose different materials according to different usage environments. Generally, a weak acid is used, and the non-corrosive normal material is stirred to select stainless steel. Carbon steel epoxy should be selected if there is strong acid material agitation. If there is a higher requirement for the service life of the agitator, carbon steel rubber is recommended.

03-18

Development trend of agitator equipment

It is required to force the concrete mixer manufacturer to introduce its new customer site. This is a good way to test the quality of the agitator equipment. If the manufacturer avoids it, the following problems will not be discussed. The agitator equipment must have problems;

03-18

Good results of the mixer manufacturer equipment

However, since the environmentally friendly small concrete mixing plant has been used, the situation has suddenly become more and more cheerful. Small concrete mixing plants have many advantages. The obvious advantages are low investment, fast profit, and because they are new equipment, they are very environmentally friendly. We don’t have to worry about a lot. Problems such as low noise, low dust, sewage treatment in place, higher utilization of concrete, etc.

0635-5085330

0635-5085330